Why Mini Screw Piles Are Ideal for Restricted Access Foundations

Why Mini Screw Piles Are Ideal for Restricted Access Foundations Table of Contents Constructing foundations on sites with restricted access can be one of the

Ultimate Screw Piling Blog

ULTIMATE SCREW PILING BLOG

Screw pile underpinning is a modern method of stabilising and strengthening existing foundations by installing steel screw piles beneath a property. Unlike traditional underpinning, which often requires large excavations and mass concrete, screw pile underpinning is less disruptive, faster to install, and suitable for sites with restricted access.

Using screw piling as a method for underpinning a foundation is a really cost effective and less intrusive way of securing property subsidence to stop any further movement due to moisture loss in the ground, trees or roots growing larger over time absorbing substantial volumns of water from the ground. Other potential causes can be broken drains, gutters or soakaways that have cracked, failed or become blocked.

If you find gaps, cracks or uneven surfaces your property is likely to be affected. Looking at points of load where there could be weaknesses such as around doors and windows; if they become sticky or tight to open / shut will help give an indication.

Our screw piling foundation system is highly suited to an underpinned foundation solution. Especially when tight access limits getting in with a larger machine to do any excavation.

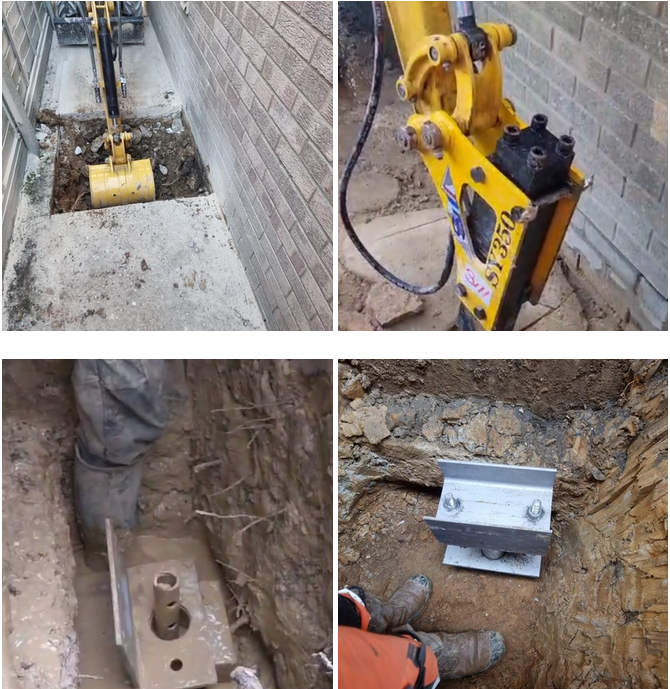

Ultimate Screw Piling have recently completed two underpinning projects in the last few weeks; the first project – access was brilliant and we were able to incorporate the underpinning with a new reinforced slab. The second project, access was so limited so we used our micro digger in order to excavate the required access to the existing property foundations that needed support.

In many cases our installers have to cut out access locations in existing concrete slabs / concrete paths etc. Once this has been done, as much excavation as possible is done with our micro digger, then finishing off the excavation by hand, in order to get enough excavated space beneath existing foundations. This allows our team to install our screw pile as close to the property as possible. Once the required torque setting has been achieved as set out by our engineering team, we slide our custom underpinning bracket onto the screw pile shaft, then torque up the bolted connection to pull the bracket as tight under existing foundations as possible.

Two stages showing our underpin pile caps – image 1 is the custom underpinning bracket that fits under the existing foundations, image 2 is the top bracket mounted on top of the pile that shows the M24 8.8 grade BZP bolts that have been torqued up to hold everything in place.

The underpinning solution was installed to the right on the small nib of the existing building. The screw piles used in this foundation solution for both the new reinforced concrete slab and the underpinning were our 50R mini screw piles.

Screw pile underpinning offers several advantages over more traditional methods. One of the biggest benefits is cost — installation is generally more affordable as it requires less excavation and labour than mass concrete underpinning.

The system also creates minimal vibration and disturbance. This makes it ideal for projects close to neighbouring properties or in sensitive environments where traditional piling might cause damage or disruption.

Because screw piles can be installed using smaller equipment, they are particularly suited to tight access areas. This means underpinning work can still be completed even when there is limited space for machinery.

Another advantage is speed. Screw piles can be installed quickly and carry immediate load capacity, so stabilisation of the property is achieved straight away without having to wait for concrete to cure.

| Feature | Screw Pile Underpinning | Traditional Underpinning |

|---|---|---|

| Installation Speed | Fast – immediate load capacity | Slow – concrete requires curing time |

| Excavation Required | Minimal | Extensive digging needed |

| Vibration/Noise | Very low | Higher risk of disturbance |

| Access | Works in restricted/tight access sites | Requires space for machinery |

| Cost | Often more cost-effective | Can be more expensive |

| Suitability | Ideal for clay soils, shrinkage, tree root zones | Works but slower and more disruptive |

Spotting early warning signs of subsidence is key to preventing further damage. If you notice cracks forming in walls, both inside and outside, this can be a strong indicator of movement in the ground beneath your foundations.

Gaps appearing between walls, ceilings, or floors should also be taken seriously, as they often point to shifting or sinking of part of the structure.

Doors and windows that suddenly become difficult to open or close can signal movement around load points, as the frames become twisted or misaligned.

Another common sign is uneven or sloping floors. If one area of a property feels lower than another, it may be a sign that part of the foundation has dropped and requires support through underpinning.

Quick Recap

Cracks in walls – visible both internally and externally

Gaps forming – between walls, ceilings, or floors

Doors and windows sticking – frames becoming twisted or misaligned

Uneven or sloping floors – an indicator of dropped or shifting foundations

If you are noticing cracks, uneven floors, or other signs of subsidence, screw pile underpinning could provide the right solution for your property. Contact the team at Ultimate Screw Piling to arrange a site assessment and find out how we can help stabilise your foundations.

Email us: [email protected]

Why Mini Screw Piles Are Ideal for Restricted Access Foundations Table of Contents Constructing foundations on sites with restricted access can be one of the

Why Screw Piling is the Sustainable Alternative to Concrete Table of Contents At Ultimate Screw Piling Ltd (USP), we’re proud to be leading the way

What is Screw Piling? Table of Contents Screw piling, also known as helical piling or helical screw foundations, is a type of deep foundation system

Taddiford House, Barton On Sea, Hampshire – Case Study Taddiford House, Barton On Sea, Hampshire Taddiford House and Garage, a new build project. This is

Ultimate Screw Piling Blog ULTIMATE SCREW PILING BLOG We are now CHAS Elite accredited! Ultimate Screw Piling Ltd have now been awarded our CHAS Elite

Ultimate Screw Piling Blog ULTIMATE SCREW PILING BLOG Screw Piling for the Construction Industry Ultimate Screw Piling Limited is an established specialist screw piling company

Our team of experts will be happy to help you with any questions you may have, and to provide you with a free, no-obligation quote for your project.